When it comes to switches, two main types are commonly used – latching switches and momentary switches. While they may look similar, these switches operate in different ways and are designed for different applications. In this article, we will explore the difference between latching and momentary switches and discuss their respective uses.

Latching Switches

Latching switches are designed to be switched on by the user and will remain on until they are manually switched off again. Once turned on, they do not require continuous compression from the user to stay activated. You can find latching switches in various settings, such as homes, where they are commonly used for light switches, central heating switches, or stereo systems.

Additionally, latching switches are used in different industries, including tattoo machines and spa operations. These switches provide a convenient way to control the operation of these devices without the need for constant pressure.

Momentary Switches

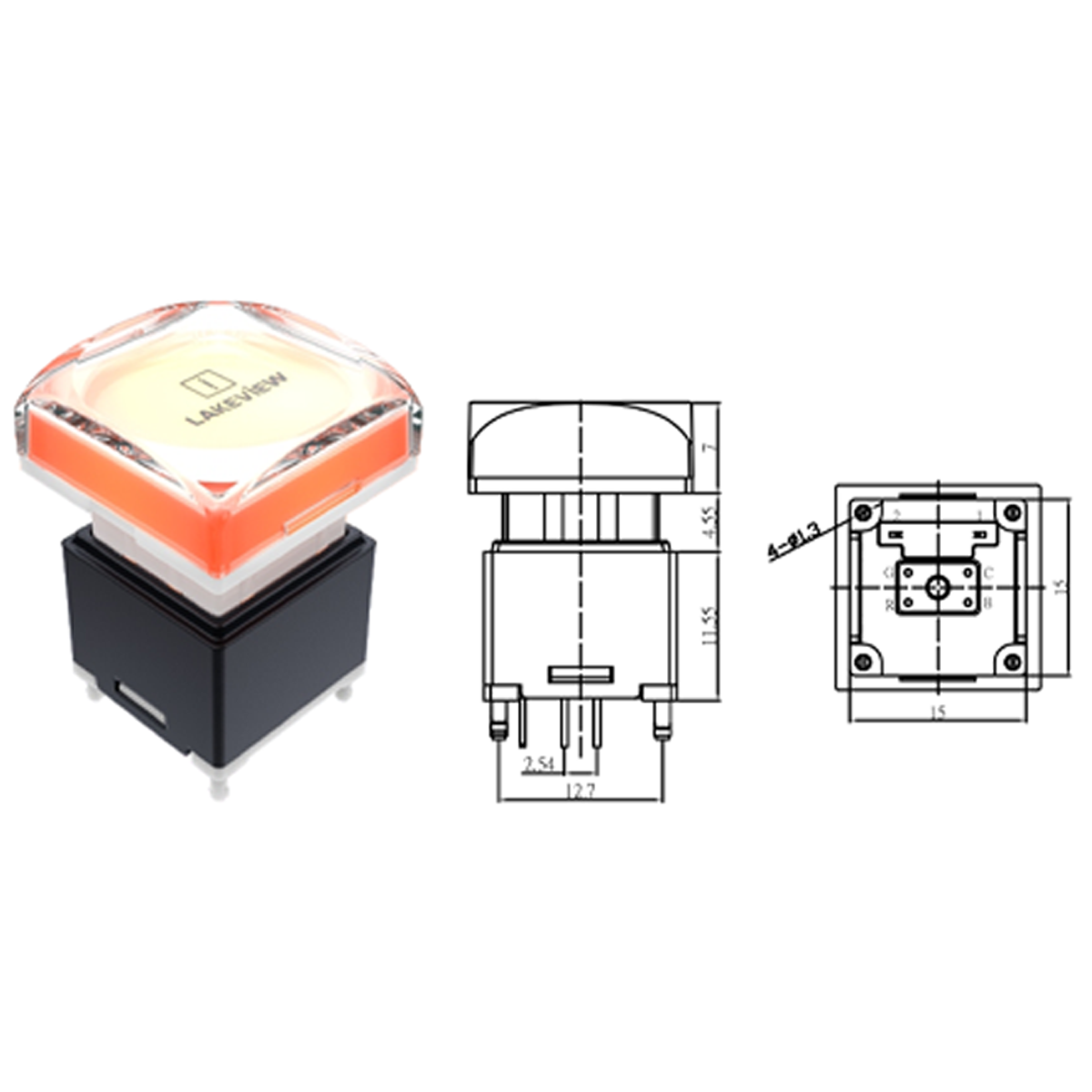

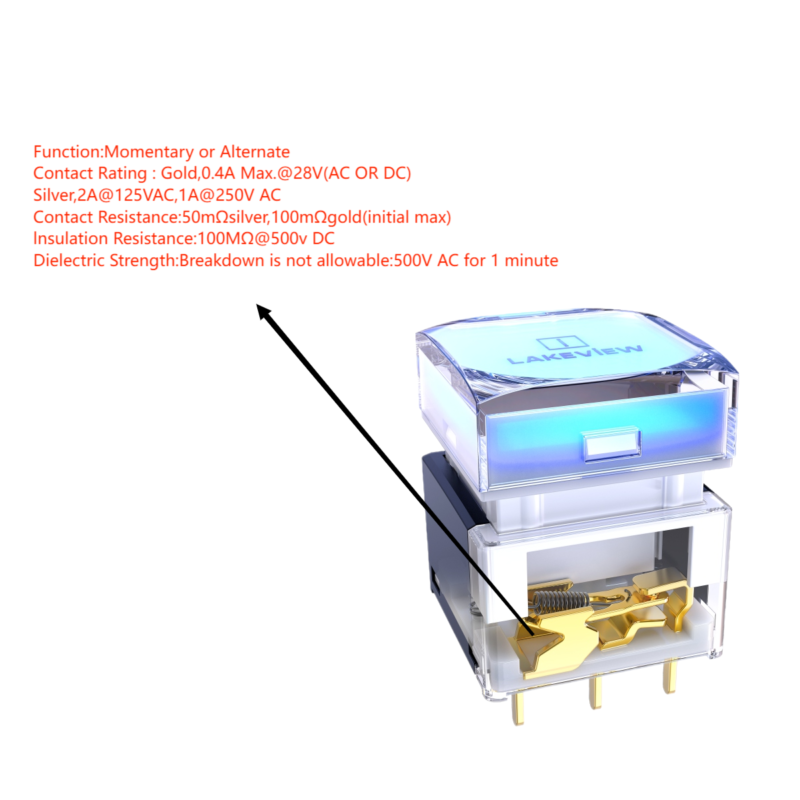

Momentary switches, on the other hand, require continuous compression from the user to stay activated. These switches will turn on when the user compresses the switch and will remain on only as long as there is pressure applied. Once the pressure is removed, they will switch off automatically.

Some common examples of momentary switches include door buzzers or electric drills. In the medical industry, momentary switches are used on hand or foot controls for hospital beds. Patients can adjust the position of the bed by applying pressure to the switch, but the bed will only move as long as the switch is pressed down. Additionally, momentary switches are used for “press to talk” applications in telephones, where the line remains open as long as the switch is pressed.

Choosing the Right Switch

The choice between a latching switch and a momentary switch depends on the specific application and safety considerations. One of the main reasons for choosing a momentary switch is operator safety. If it is not safe for the device to be left unattended, a momentary switch ensures that the operator must continuously apply pressure to keep the device activated.

For example, heavy-duty roller doors often use momentary switches. The operator must hold down the switch while the door is opening or closing. If there are any obstructions in the doorway, the operator can quickly release the switch to stop the door from closing, preventing accidents.

Latching switches, on the other hand, are more suitable for lower-risk applications and situations where it would be highly inconvenient for the operator to manually apply pressure to keep the switch activated. For instance, it would be impractical to stand at a light switch to keep it switched on, so a latching switch is a better choice in such scenarios.

In conclusion, latching switches and momentary switches serve different purposes and are suited for different applications. Understanding the difference between these switches allows you to make an informed decision when choosing the right switch for your specific needs.